Many are the elements that participate in the request of a rapid prototyping service and some of these are more crucial than others, it is special for the client.

When you have in mind to request a rapid prototyping service there are many terms that must be established in conjunction with the company that will create the parts, and it is important that these are fairly clear since any confusion could be reflected in the result of the final product and this it would affect the production and also the tests that are required to be done with it and its functionality.

The quantity of pieces that are required will determine the price of the service.

One of the main issues on which the manufacturer and the applicant must agree is to establish the quantities of parts that will be manufactured in order to establish an appropriate production price with the order. This is an issue that causes a great headache for many customers, because many companies, although it is a rapid prototyping service, charge this procedure as if it were any other, and in reality these are cheaper.

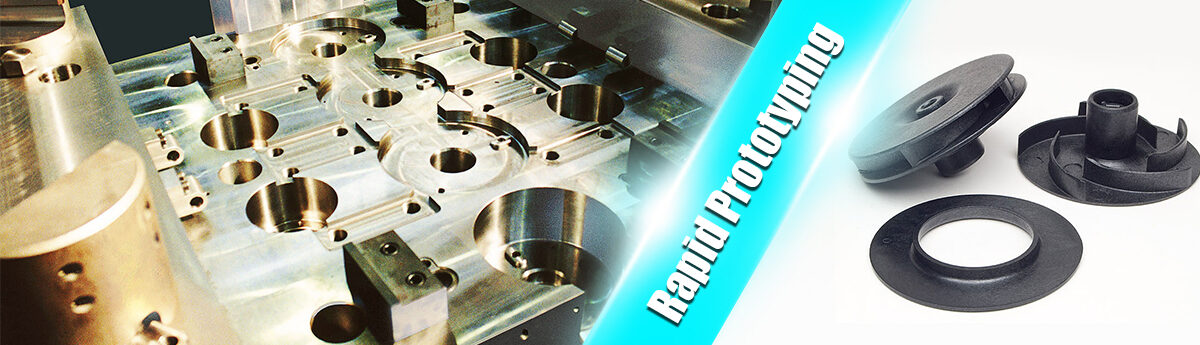

Rapid prototyping is a common technique for manufacturers to evaluate in detail the behavior of a new design in their products.

Most of the clients that order a rapid prototyping service do so because they need to make some type of test product to renew the services of a new version of a piece, or perhaps observe the behavior of a new design, among other required tests.

These techniques used in rapid prototyping service are able to reduce production costs considerably and can also shorten the time, depending on what characteristics the various designs proposed by the client may present.

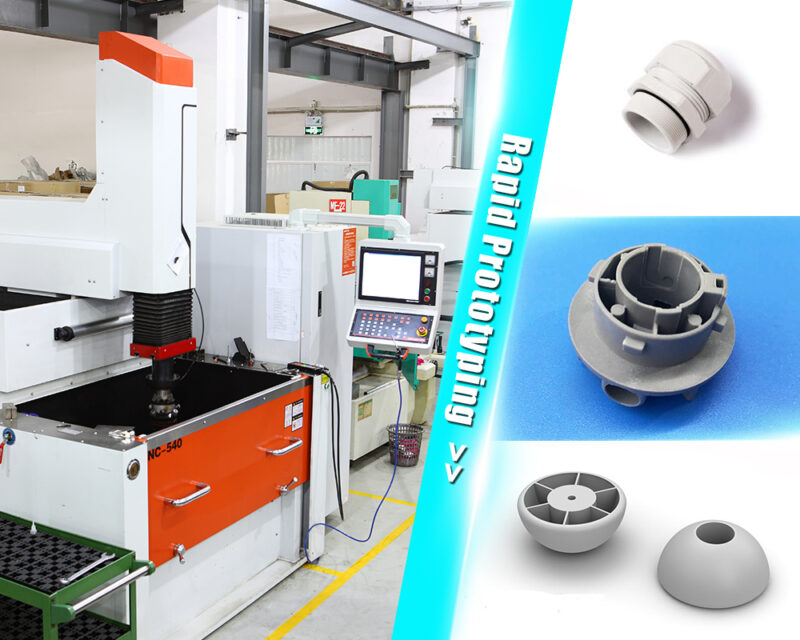

One of the best manufacturers that offers a rapid prototyping service and includes a long list of available methods for this is Start Prototyping, and could not improve the delivery time and in addition to this the price.

Production costs are fundamental factors that are involved in the relationship between the customer and manufacturers, especially if it involves the realization of a test piece, therefore it is important that the offers are attractive to customers, otherwise These would be very limited at the time of requesting this type of services as it would not represent any advantage compared to mass production.

In Start Prototyping the lowest market prices are offered, without compromising the quality, strength or functionality of the product. The cost of a service of this type is 40 to 60% of the usual cost of other companies and this will save you almost half of your money in costs for the prototypes you need for your company.

Start Prototyping has worked very hard for 10 years to position itself as the best before other companies that are also engaged in mass production, and has managed to be quite successful, this thanks to the modernity of all its processes, the quality of its products and the speed of delivery.

For more about rapid prototyping service,you can pay a visit to https://www.startprototyping.com/

About Start Prototyping

Start Prototyping mainly supply our rapid prototyping service and plastic injection manufacturing for many 3D print companies in the world.

Start Prototyping has been engaged in rapid prototyping about 10 years, helping too many designers to turn their ideas into reality. Most of the conceptual prototype of the design has been successfully put into the market and has achieved good benefits. Among them, the most representative metal prototype machining, plastic prototype machining, CNC aluminum machining, Low-Volume Manufacturing, processing technology including CNC machining, vacuum casting, rapid tooling, 3D printing and so on. We have the standard quality inspection process, which is completely in line with the customer’s industrial design. It’s a great honor to be a partner with you.

Contact Info

Contact:James Yuan

Company:Start Prototyping

Add:LongGang Village, LongXi Town, BoLuo County, HuiZhou City,GuangDong Province, China

Tel:+86-13352636504

Email:info@startprototyping.com

Web:https://www.startprototyping.com

Company:Start Prototyping

Add:LongGang Village, LongXi Town, BoLuo County, HuiZhou City,GuangDong Province, China

Tel:+86-13352636504

Email:info@startprototyping.com

Web:https://www.startprototyping.com

Pearltrees:https://www.pearltrees.com/jasonmould